GRAPHENE ALUMINIUM-ION BATTERY PROTOTYPES SENT TO CUSTOMERS FOR TESTING AND EVALUATION

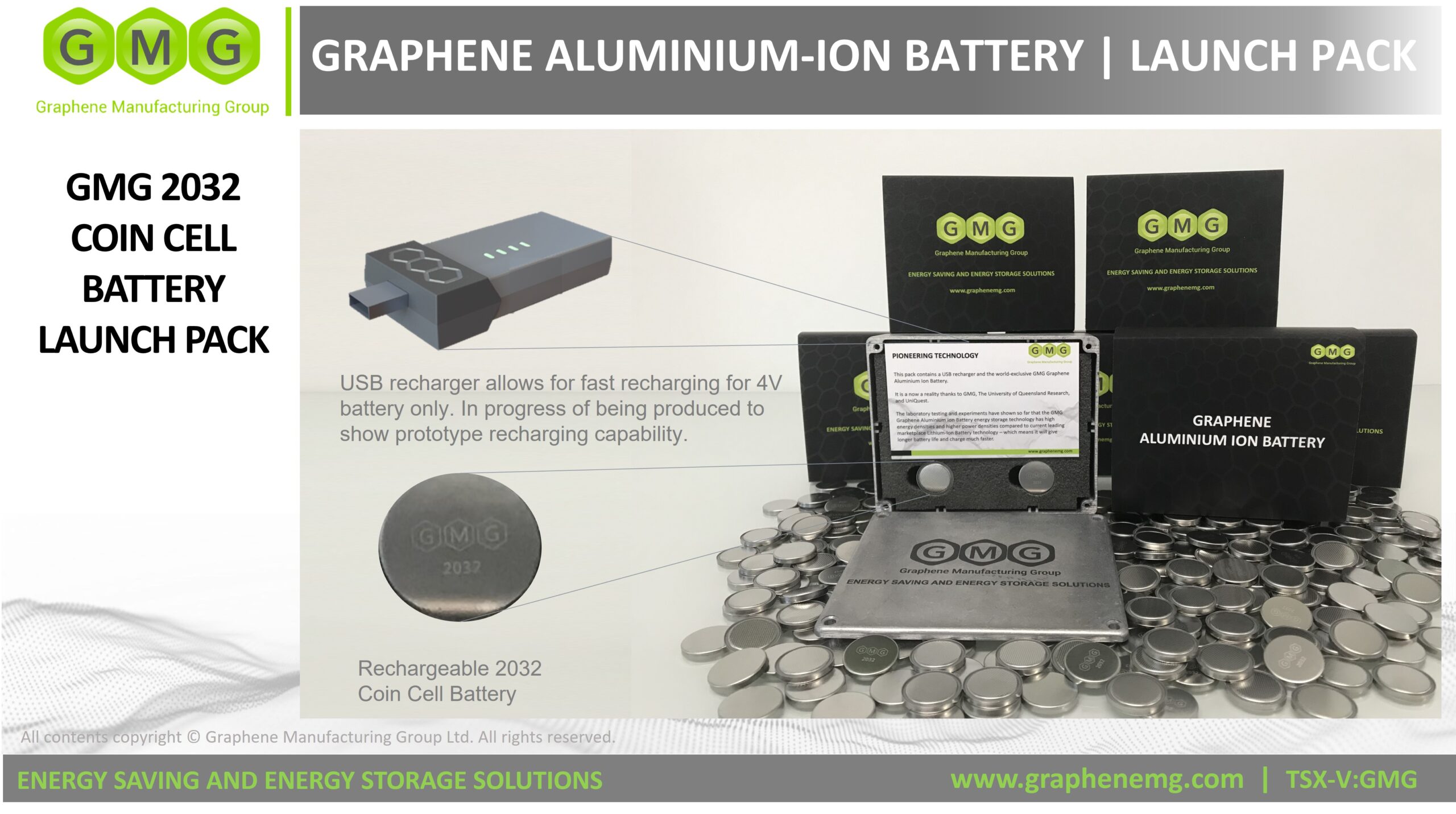

BRISBANE, QUEENSLAND, AUSTRALIA – December 22nd, 2021 – Graphene Manufacturing Group Ltd. (TSX-V:GMG; FRA:0GF) (“GMG” or the “Company”) is pleased to announce that its graphene aluminium-ion batteries (“G+AI Battery”) 2032 type coin cell prototypes (see Figure 1) have been sent to a number of prospective customers around the world.

Coin cell testing to date has demonstrated that the GMG 2032 type G+AI Battery coin cell prototypes are fully rechargeable in several seconds, retain capacity for several thousand charge and discharge cycles, are non-flammable, and are relatively non-toxic and almost fully recyclable. These characteristics compare favourably against typical rechargeable Lithium-Ion 2032 type coin cells which take 3-6 hours to recharge, are toxic and can be quite harmful if ingested, are difficult to recycle, are flammable under certain conditions, and degrade more rapidly in performance.

Figure 1: GMG 2032 1.7V Prototype

GMG is pleased to report that further battery development, in collaboration with the University of Queensland, has increased the capacity of the G+AI Battery coin cells, when compared to earlier proof of concept prototypes. The Company is also currently in the process of developing the technology required to increase the voltage of the coin cell from approximately 1.7 Volts to 3.4 Volts – making the G+AI Battery better suited for interchangeable use in existing everyday personal devices. In addition to graphene manufactured by GMG, the Company also continues to test different grades of graphene from various sources for use in G+AI Batteries. GMG considers the performance characteristics of these prototypes clear enough to engage potential customers and industry partners for feedback on their commercial potential following subsequent further development.

GMG’s CEO and Managing Director Craig Nicol said: “We are very pleased with the technical and commercial progress we have made to date on our G+AI Batteries, and with the level of interest received from potential customers. We look forward to customer feedback on these prototypes, and to progressing towards the commercialisation of this impressive battery technology. In parallel we will continue to optimise and improve performance in our newly commissioned pilot plant and start to develop pouch pack formats during 2022 in addition to the coin cell.”

About GMG

GMG is an Australian based clean-tech company listed on the TSX Venture Exchange (TSXV:GMG) that produces graphene and hydrogen by cracking methane (natural gas) instead of mining graphite. By using the company’s proprietary process, GMG can produce high quality, low cost, scalable, ‘tuneable’ and no/low contaminant graphene – enabling demonstrated cost and environmental improvements in a number of world-scale planet-friendly/clean-tech applications. Using this and other sources of low input cost graphene, the Company is developing value-added products that target the massive energy efficiency and energy storage markets.

The Company is pursuing opportunities for GMG graphene enhanced products, including developing next-generation batteries, collaborating with world-leading universities in Australia, and investigating the opportunity to enhance the performance and energy efficiency of engine oils, biodiesel and diesel fuels.

For further information, please contact:

– Craig Nicol, Chief Executive Officer and Managing Director of the Company at [email protected], +61 415 445 223

– Leo Karabelas at Focus Communications, [email protected] , +1 647 689 6041

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accept responsibility for the adequacy or accuracy of this news release.

Cautionary Note Regarding Forward-Looking Statements

This news release includes certain statements and information that may constitute forward-looking information within the meaning of applicable Canadian securities laws. Forward-looking statements relate to future events or future performance and reflect the expectations or beliefs of management of the Company regarding future events. Generally, forward-looking statements and information can be identified by the use of forward-looking terminology such as “intends”, “expects” or “anticipates”, or variations of such words and phrases or statements that certain actions, events or results “may”, “could”, “should”, “would” or will “potentially” or “likely” occur. This information and these statements, referred to herein as “forward‐looking statements”, are not historical facts, are made as of the date of this news release and include without limitation, statements regarding the continued optimisation of the G+AI Battery, the potential toxicity and recyclability of the 2032 type G+AI Battery coin cell prototypes, the technological development and optimisation of the G+AI Battery coin cells, the potential commercialization of the 2032 type G+AI Battery coin cell technology, the optimisation and improved performance of the Company’s pilot plant, and the development of the 2032 type G+AI Battery coin cell prototype in a pouch pack format.

These forward‐looking statements involve numerous risks and uncertainties and actual results might differ materially from results suggested in any forward-looking statements. These risks and uncertainties include, among other things, risks related to the deployment of the Company’s resources, including its personnel, and the intention of the Company to research, develop and produce certain products and technologies, the ability of the Company to optimise certain products and facilities, and the commercial progress and technical characteristics of certain products.

In making the forward looking statements in this news release, the Company has applied several material assumptions, including without limitation, assumptions regarding the Company’s ability to research, develop and test its products within anticipated timelines, and market demand for the Company’s products.

Although management of the Company has attempted to identify important factors that could cause actual results to differ materially from those contained in forward-looking statements or forward-looking information, there may be other factors that cause results not to be as anticipated, estimated or intended. There can be no assurance that such statements will prove to be accurate, as actual results and future events could differ materially from those anticipated in such statements. Accordingly, readers should not place undue reliance on forward-looking statements and forward-looking information. Readers are cautioned that reliance on such information may not be appropriate for other purposes. The Company does not undertake to update any forward-looking statement, forward-looking information or financial out-look that are incorporated by reference herein, except in accordance with applicable securities laws. We seek safe harbor.